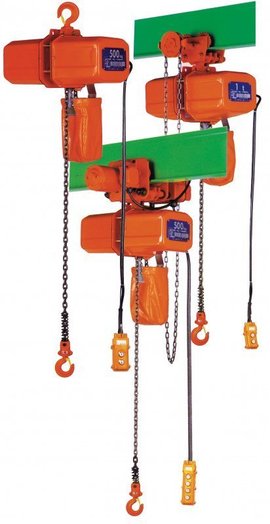

Nitchi EC-4 Electric Chain Hoist

EC-4 ELECTRIC CHAIN HOIST

Capacities – 250, 500, 1000kg and 2000kg (in 3-Phase) and 300, 500 and 1000kg (in Single Phase)

Options of Hook Suspension, Manual Trolley, Electric Trolley

Nitchi EC-4 Electric hoists feature:

Heavy Duty Motor

The Class ‘B’ insulation of the high performance motors is capable of coping with most materials handling applications.

Wear Resisting Load Sheave

The special load sheaves engage precisely with the load chains and are specially thermo-refined to make them long-wearing.

First Stage Helical Gearing

The precision helical gears in the first stage of the reduction gear system largely reduce gear tooth impact and operating vibrations. This is one of the main reasons for the quiet, long, dependable life of the ECT-4 Series.

Easy Cable Couplings – NEW!!

The new Easy Cable Coupling system makes it possible to easily and quickly attach, detach or replace the pendant and cables.

Push Button Switch

The strong, lightweight push button switch responds immediately to a light touch of the button.

Chain Bucket / Bag

Each hoist is supplied with a chain bucket as standard equipment.

Space Age Materials – NEW!!

The remarkably durable, lightweight resinoid centre-frame and cover provide tight fits that notably improve dust and moisture protection and assist to lower operating noises. The bodies have IP 54 and the pendants have IP 64 ratings.

Steel Construction

The main frame consists of two rugged steel plates that provide maximum protection against dynamic loads.

Ultra-Tough Load Chains

The NITCHI case-hardened load chains are made from special alloy steel and are given super-tough, carbonized hard surfaces that resist abrasion several times longer than conventional through-hardened load chains. The soft core section gives theload chain the elasticity which is essential for material lifting equipment. Every link of load chain is tested and a record of each chain production lot is kept on record at the Nitchi factory.

Forged Steel Hooks

The top and bottom hooks on all capacities are made of dropforged steel that is heat-treated for greater strength. Every bottom hook is equipped with a thrust bearing for smooth rotation and has a safety latch as standard equipment.

Over Lifting and Over Lowering

The over lifting and over lowering limit switch system is one of the most important safety devices on an electric chain hoist. A. Buffer Springs located on both ends of the load chain. B. Limit Lever which positively activates the limit switch system when the hoists are over lifted or over lowered. C. Limit Switch that instantly stops the hoist when over lifting or over lowering.

Simple Two Speed Operation

The 4 to 1 speed ratio of the Model ECT-4 is ideal for a large variety of applications and the slow speed works accurately when spotting the load to a desired position. By utilising the fast speed the load can be quickly and efficiently handled. The slow and fast speeds are both completely at your command with the dual-stage

push button pendant control. For slow press the buttons half down, and the fast speed can be obtained by completely depressing the buttons.

Durable Brake

The solenoid brake system responds instantly and will safely support the load if power failure occurs. This brake system has proven to be extremely long wearing and will keep servicing costs down.

Short Head Room

The ingeniously designed compact construction allows the highest possible lift to be obtained.